User Manual of GE-102 Sludge Depth Level Meter

1. Product Overview:

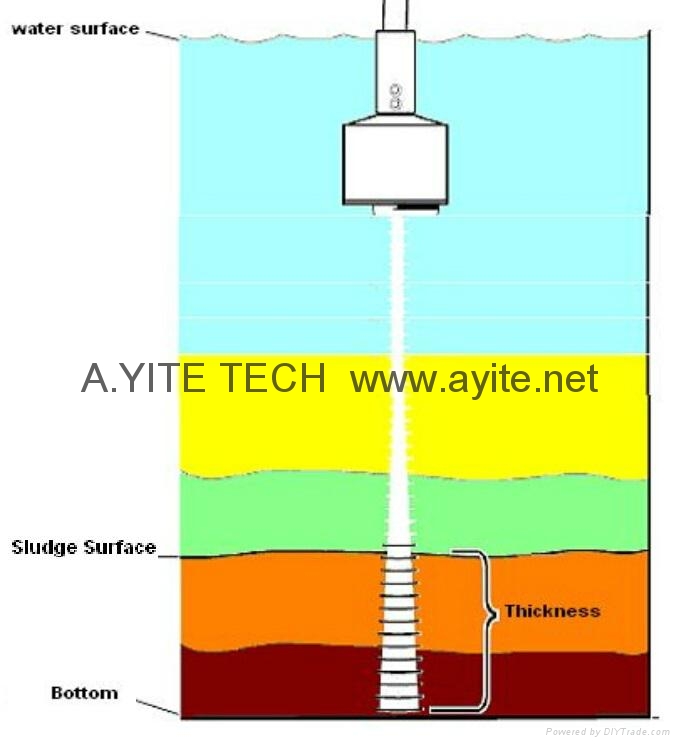

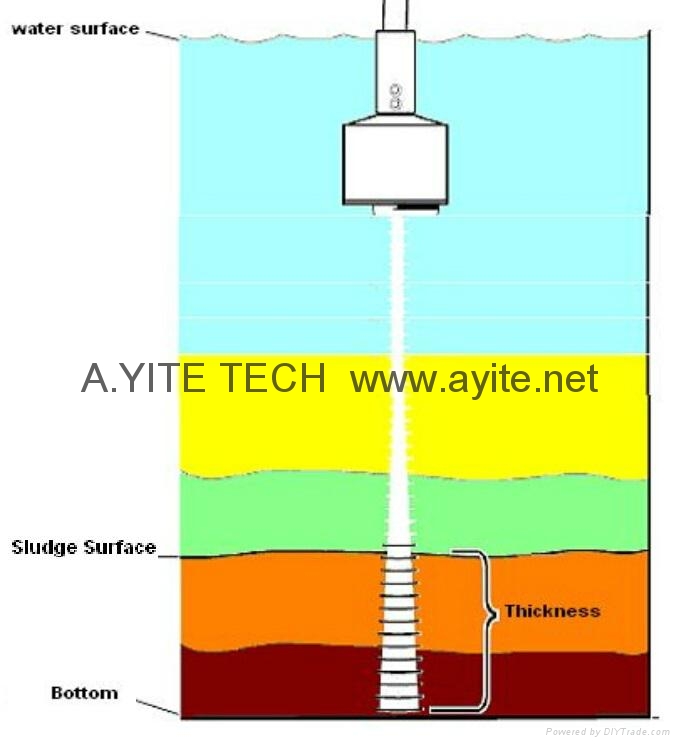

GE-102 ultrasonic sludge depth meter, also known as sludge level meter and sludge water interface meter, is specially designed for continuous on-line monitoring of sludge interface position in sewage treatment process. The instrument uses the reliable ultrasonic echo detection principle to detect the distance between the sensor probe and the sludge interface and the distance between the bottom surface. It realizes the real-time monitoring of 0-10m sludge thickness change and the control of related process, so as to optimize the sludge discharge control and dosing control, prevent the deterioration of the effluent, avoid the denitrification and decomposition of sludge, and optimize the process control flow.

This instrument adopts the advanced technology of ayt company, and has perfect measurement function, control function, data transmission function and man-machine communication function. This machine is an interface position measuring instrument which integrates ultrasonic transceiver sensor, servo circuit, temperature compensation sensor and compensation circuit unit, display, control signal output and serial data or analog output unit (optional).

2、 Application:

Water supply plant: sedimentation tank

Sewage treatment plant: primary sedimentation tank, secondary sedimentation tank, concentration tank, etc

Coal washing plant: sedimentation tank

Power plant: mortar sedimentation tank

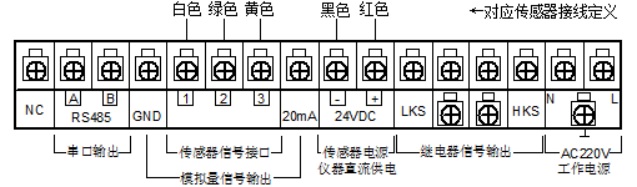

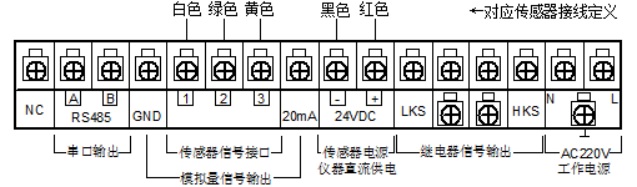

3、 Wiring method and diagram of sludge depth meter

The ultrasonic interface meter sensor and instrument are matched and cannot be interchanged; the sensor and instrument cable are our company's special cable, standard 5m. In order to obtain better measurement results, the sensor cable should be installed in the way of pipeline auxiliary.

Wiring diagram of sludge depth meter

4、 Key function

[PAG] page turning key: press this key in the working state to display P1, and then press the shift key to enter into the setting or browsing of each parameter item in P1 menu. Press the page turning key once to display the next menu, a total of 15 items.

[mov] shift key: in the setting state, press this key to shift. When each number is set, press this key until all numbers are flashing, which is the setting parameter storage operation. Then press the page turning key to enter the next item.

Press this key to turn on the display when the display is off in power saving mode;

Press this key in working state for 3 seconds to turn on backlight, and then press it for 3 seconds to turn off backlight.

[add] add key; press this key in the setting status to add "1" to the number of flashing digits and determine the decimal point. When a minus sign is required, press this key to call out or remove the minus sign; press this key in the working status for 3 seconds to close the display, enter the power saving mode, and press the shift key to open the display; press this key in the working status to realize the display conversion of [output analog quantity / current temperature].

5、 Menu and parameter setting

Menu entry

In the working state, press the page turning key to display P1, and then press the shift key to enter the P1 user operation menu, which is displayed as follows:

L1 x x x x

The first limit alarm output: L1 < L2 < L3 < L4, use the shift key to shift, add the number to the flashing position, input the required limit value, and press the shift key again when the lowest position is flashing. At this time, when all four bits of the set parameters are no longer flashing, press the page turning key to save the set parameters and enter the next item menu.

L2 x x x x

Second limit alarm output: the operation method is the same as L1.

L3 x x x x

The third limit alarm output: the operation method is the same as L1.

L4 x x x x

The fourth limit alarm output: the operation method is the same as L1. (the above items L1-L4 are used when selecting limited value alarm output mode)

E x x x x

Sensor draft setting. The sensor of ultrasonic interface instrument can work only when it is in the liquid. Therefore, the sensor installation must have a certain draft.

E value this setting has two applications:

1. The user requires to measure the height from sludge surface to water surface - at this time, e value is the sensor draft: - XX (negative value);

2. The user requires to measure the height of sludge layer - at this time, e value is the installation height from the sensor launching plane to the pool bottom: XX (positive value);

Parameter setting method is the same as L1

N x x x x

When the salinity is 0, it is used to measure the sludge interface of fresh water. When it is used to measure the sludge interface of sea water, corresponding parameters are input according to the current salinity of sea water. For example, when the salinity is 3.6%, the n value should output 0.036.

Parameter setting method is the same as L1

D x

This function is used to communicate with the upper computer when multiple computers are online. The effective value is 1-128. Parameter setting method: press the add key once to add 1, and press the shift key once to subtract 1. The default value is 0. (for serial output products)

Bo x x x

The baud rate of communication is set as: 0.3, 0.6, 1.2, 2.4, 4.8, 9.6, 19.2kbps. Parameter setting method: press the add key to increase, and press the shift key to decrease. (for serial output products)

P x

Transmission power setting, maximum level 11 or 15 (depending on the model), can be modified according to the working condition setting with the add key, from 1 to 15, from small to large (in order to be stable and accurate, generally according to the factory setting value). The setting method is the same as Bo

C x x x x

The current measured water temperature, this menu can only be observed, can not be modified.

CA x x x x

The output analog value corresponding to the current measured interface can only be observed and cannot be modified in this menu. (for analog output products)

Exit menu

After setting the menu parameters, press the page turning key for 3 seconds to exit the P1 menu and enter the normal working state.

6、 RS-485 serial port protocol of sludge depth meter:

Half duplex asynchronous mode; baud rate 9600 BPS; MC version communication format (standard baud rate)

1. Host: send address (1-64) binary source code and then query the received data

2. Slave: reply in interrupt mode, 21 bytes per frame

Order of data sent from slave

The first five bytes are: interface location value (5-byte ASC code)

The 6th-20th byte is the production test code (with the user